Triple Package

The Weekly Report – March 4, 2024

Three company profiles highlight the widespread advantages of ISO certification.

When the next issue of Enterprise Minnesota® magazine hits your mailbox in the next week or so, you’ll find a trio of articles in which manufacturing executives describe how ISO certification helps their companies grow.

While the articles provide an inside look at several strategies behind three very well-led companies, their experiences with ISO are timely for two reasons. First, our most recent State of Manufacturing® survey showed that just 18 percent of manufacturers across the state are ISO certified. Of those that are not, just seven percent plan to pursue certification in the near future. Manufacturers with certification are in an elite group and have a clear advantage in the marketplace.

Second, as manufacturers are not contending with supply chain bottlenecks, runaway inflation, or crisis-level worker shortages, they have an excellent window to pursue ISO certification.

As you’ll read, each company had different motivations for embracing ISO, and each experienced significant benefits from certification. From reaping the benefits of greater production efficiencies, to increasing attractiveness to potential investors, to reaching a broader market, ISO gives manufacturers a solid leg up on the competition.

At Van Technologies Inc., a Duluth-based manufacturer of environmentally friendly coatings, earning ISO-certification kicked off a company-wide commitment to process improvement. During a COVID-related slowdown in production, Van Technologies quickly obtained ISO certification and has since used the quality management tool to boost productivity and strengthen its team.

Larry Van Iseghem, the company’s president and CEO, says his ISO operation is more efficient and cost-effective, achieving a 34 percent increase in output without adding much additional staff. In fact, the company’s production per labor hour has jumped by more than a third since the pandemic disruption.

Teresa Donahue, the technical manager at Van Technologies, says ISO created a common goal. “Having all of our employees engaged in this process and our quality objectives has created more of a team environment,” she says.

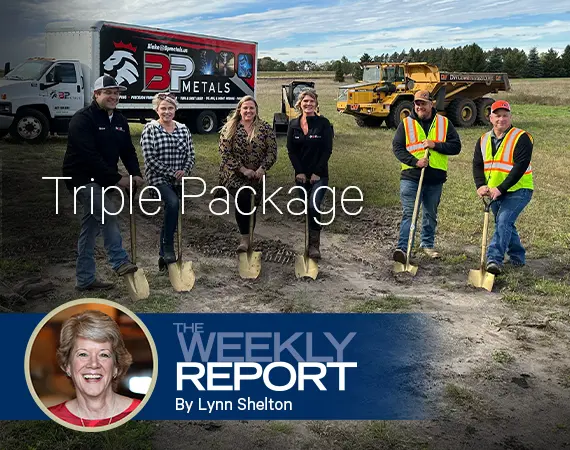

When BP Metals founder Blake Pendzimas started looking for investors to help him grow his company, potential partners found several aspects of his metalworking shop very attractive. The Isanti-based company had more than tripled sales in three years, landing it on the Inc. 5000 list of fastest-growing private companies. The company moved from Blaine to founder Blake’s hometown of Isanti and is in the process of doubling its 10,000 square foot production facility to keep up with current and anticipated growth. And, at the end of 2023, BP earned ISO 9001 certification.

Those factors, particularly the ISO certification, attracted Generation Growth Capital, which purchased the company in October, and kept Pendzimas on as an owner and leader of the operation. John Reinke, managing director of Generation Growth Capital, says ISO certification shows that BP Metals is receptive to positive change and operational advancement. He also expects it to increase BP’s opportunities to secure work as a tier 1 supplier to OEMs that demand ISO 9001 partners.

Spectro Alloys began in 1973 as a small scrap yard that melted aluminum for reuse. In 1989, Greg Palen gathered investors and bought the operation; the 150-employee Rosemount company now recycles aluminum into casting alloys for foundries and die casters. Early on, Palen and his team invested in technology to boost efficiency, automation, quality, and pollution control. They also pursued certification in standards like ISO 9001.

Spectro’s vice president, Gary Borner, says ISO confirmed that everyone on the team knew what the processes were and that they were followed. Earning certification marked an important milestone for the company. “It was a good transition because not only was Spectro improving process-wise in the plant, we were gaining more visibility and more communication with a broad group of customers as a result of the certification process,” he says.

For more detail on these companies check out the Spring 2024 issue of Enterprise Minnesota® magazine, and for more information on how Enterprise Minnesota can help your company achieve ISO certification, contact us today.

Industry News

Manufacturing workers needed in Southeastern Minnesota

March 1, KIMT3 News

Aberdeen, SD manufacturing plant that employees over 300 to close

March 1, South Dakota Public Broadcasting

RION Expands Manufacturing Operations with Cutting-Edge Facility in Rochester, Minnesota

February 26, Business Wire

Duluth-based Cirrus Aircraft sales soar; Company brand adopts new look

February 26, Duluth News Tribune