In 1990, Phil and Roberta Johnson and their sons Jim and Tom set up shop in the machine shed on their Roseau farmstead and started mounting tires on rims for the nearby Polaris plant. They thought a three-month summer operation would provide a good supplemental income for the family farm. Fast-forward to 2024 and that family business has plants in four other locations including two other countries, basically following wherever Polaris has opened plants.

That first summer was just what the Johnsons hoped it would be, but then Polaris announced they were going to year-round production in 1991. The Johnsons incorporated as Intercept Industries, Ltd, and moved the tire-mounting operation to the old AMCO building a few miles west of Roseau. Another company affiliated with Polaris also operated out of the AMCO building, but by the spring of 1993, both operations needed more space. The Johnsons set up temporarily in a pole shed in Roseau while building a new plant west of town for offices and for the tire-assembly.

As Polaris grew, the tire-mounting business grew. Between 1994 and 2016, Polaris opened plants in Spirit Lake, Iowa; Huntsville, Ala.; Monterey, Mexico; and Opole, Poland. All have Intercept shops nearby, dedicated to support Polaris recreational and off-road vehicle production.

When they started out, Phil, Roberta, Jim, Tom, sister Jenny, and brother-in-law Brian did full assembly and hired Penner Transport to deliver the mounted tires to Polaris. From 1992 until 2018, Intercept purchased the tires and wheels and sold the assemblies to Polaris, but today Polaris owns the tires and rims, and Intercept’s role is strictly assembly, tying the two companies’ workloads and schedules closely together.

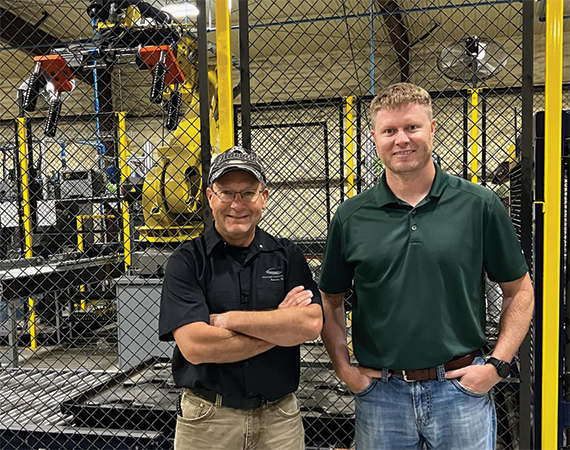

In 2007, Phil and Roberta sold the business to Jim and Tom. Today Intercept has 24 full-time employees, nine dedicated to tire and wheel assembly, and three drivers for delivery with Intercept-owned tractors.

Fortunately, business for Polaris has been steady. During COVID, many stimulus checks went to purchase recreational vehicles. Polaris had huge back orders, and even as the number of new orders declined, the backlog continued through 2023. Today Roseau’s Intercept plant averages about 1,200 tire assemblies per day.

Finding and keeping good employees is key

Nathan Voll, Intercept’s chief financial officer, grew up in Roseau and had hoped to return to the area after college, which he did in 2012 when a position opened at Intercept. Voll says the friendly atmosphere of the family-owned and run business helps the company keep workers, and Intercept invests back into the company and its employees.

Fourteen of Intercept’s employees in administrative support or production have been with the company for more than 10 years — three of them over 20 years, and their operations manager, for 19 years.

The physical demands of tire mounting led Intercept to automated solutions that have eased the assembly process and opened up more options for people of different ages and physical abilities to do the assembly work. Today tires and rims move along an assembly line, are positioned, seated, identified as front or rear tires, and sent down separate lines. A camera inspects the mounted tires before they move on.

Mounted tires are inflated at an “air up” station by an employee who doesn’t have to lift or move the wheels. An automated dispenser moves pallets into loading position and a robot does the heavy lifting, picking up each assembly and placing it as prescribed for Polaris’ needs. Pallets of tires move down the conveyor line, and an automated stretch wrapper circles the pallet several times to secure the assemblies, ready to be fork-lifted and delivered.

The unique relationship and interdependence between Intercept and Polaris have worked for three and a half decades, but to fill in during less busy times, Intercept offers production machine shop services, plastic trimming, custom welding, fabrication, and warehouse services for Polaris and other customers.

Return to the Winter 2024 issue of Enterprise Minnesota® magazine.