The excitement was palpable when the Lakeville North High School students got their rat rod go-kart engine running for the first time. The teenagers cheered, high-fived, and perhaps even shed a few tears of joy. Months of challenging work in their Manufacturing, Metals, & Welding class to design, fabricate, and assemble a made-from-scratch vehicle resulted in the revving, proving they were heading in the right direction.

The students are competing with a Minneapolis Public Schools team based at Roosevelt High School to deliver a running, drivable go-kart by the end of the school year. The test drivers of these machines? None other than NASCAR superstar Richard Petty and renowned motorcyle builder Billy Lane.

Kevin Baas, a teacher in the STEM Engineering and Innovation department at Lakeville North, says that his students are so pumped to work on their go-kart that he can barely take attendance before they race into the shop. “As a teacher, this is a win-win,” Baas says. “They want to work on it immediately. They are learning tools and fabrication and engineering, and they are learning real world skills that will make them successful.”

Fueling the competition are the professional-grade, spanking new tools that students are using to build their go-kart, plus a NorthStar engine, all of which came from Northern Tool + Equipment’s Tools for the Trades™ high school program launched in 2021 in honor of the company’s 40th anniversary. Tools for the Trades gives back to the communities where it has retail stores and inspires more youth to pursue trades-based careers.

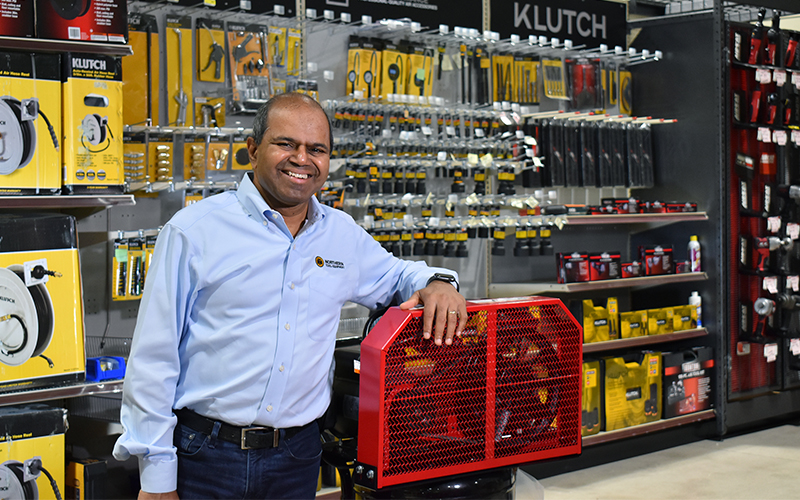

“Our mission is to honor and serve people who do the tough jobs. Think about the people in the trades tackling tough jobs every day — we want to pay tribute to them,” says Suresh Krishna, CEO of Burnsville-based Northern Tool. “We looked around and decided that the best way to do that is to build the next generation of tradespeople.”

Addressing a shortage

A host of industries contend with a deficit of skilled tradespeople, with more young people gravitating lately toward four-year degrees. The need for people to fill jobs in sectors like manufacturing, HVAC, plumbing, construction, and automotive has been a pressing challenge in Minnesota and across the country for years. Retail staff at Northern Tool’s 140 stores hear repeatedly from customers that they are looking for employees — do they know anyone?

An idea took shape to connect with nearby high schools and donate tools to their career and technical education (CTE) classes, says Darcy Betlach, director of experiential marketing at Northern Tool. “Our customers are people who work with their hands for a living, and we’ve heard from so many folks that they are really struggling to get people in the pipeline to learn their trade,” Betlach says. “As we heard that over and over, the idea formed. Maybe we can encourage schools not to shut shop classes by providing professional-grade tools and equipment.”

Northern Tool formed a nonprofit within its corporate foundation to expand giving in the 24 states where it has stores. Tools for the Trades now donates between $5,000 to $20,000 of equipment to each school, often leveraging relationships with vendors or other businesses to make the more sizable contributions.

And it’s not just about the donation of goods, Krishna says. Tools for the Trades also brings in professional tradespeople or Northern Tool employees to share their knowledge with teachers and students. They often conduct master classes in welding or metalworking, share day-in-the-life information, and provide outside opportunities like job shadowing.

“We go in and work with teachers based on the curriculum they provide and what students need,” Krishna says. “Many CTE programs work with outdated equipment. We want to provide students with the opportunity to work with the latest equipment and provide opportunities so they can be better informed about their career choices.”

Welding has been growing in popularity in recent years, prompting Tools for the Trades to often donate items like welders, welding gloves, jackets, hoods, consumables — anything that will enable more students to weld at the same time. At automotive-focused programs, it might donate air compressors, sanders, grinders, and pneumatic tools to expand the number of students learning how to do mechanical repairs or restorative body work.

Tools + support

Tools for the Trades contributes to about 10 schools a year, focusing on underserved communities as much as possible. It finds out what would be needed most, determines what it will donate, and then reaches out to vendors to see if they’d like to join the effort. Finally, Betlach gets to work to publicize the gift, and in select locations, holds a showcase with celebrities like Petty and Lane to draw press attention to career and technical education.

“They bring their clout to the table and donate their time to drive awareness of the critical issue at hand, which is the skilled labor gap,” Betlach says. “We create B-roll that we can share with the media to drive awareness for CTE and get these communities excited about having their kids try shop classes.”

Even after the cameras turn off, the support continues. Northern Tool then connects teachers with one of its retail or wholesale teams, providing a preferred account that allows schools to purchase consumables or other equipment at deep discounts, Betlach says. A customer service rep helps them with all the details like handling procurement through their school district.

Getting an email from Tools for the Trades asking if the teachers would like to receive donations of new equipment was a happy surprise at both schools. CTE classes are expensive to run, and it’s often a key target for budget cuts, Baas says. Minneapolis automotive teachers Zac Humphrey and Luther Kominski note that it’s common to run short of funding for consumables and updated tools. This causes a backlog of students waiting to get their hands on tools during class because there just aren’t enough to go around.

Both schools received a bounty from Tools for the Trades. Roosevelt’s new gear includes personal safety equipment for the entire classroom, six tool kits, an English wheel for metal shaping, tools and air compressors from Ingersoll Rand, and more. “It’s really freed up the wait in class having all of these tools,” Humphrey says. “They are in better condition and better quality and there are more available, so you don’t have students sitting around waiting to do the work they need to do to complete the class.”

Enthusiasm for the rat rod build-off has been off the charts in Minneapolis, too. Students love the opportunity to consult via video with their mentor Lane, asking questions and bouncing around ideas. Some team members even asked their teachers if they could come in during spring break to work on the go-kart. “Class ends and they want to stay. They want to come down with passes during other classes. We can’t get rid of them,” jokes Kominski.

The automotive program at Roosevelt has between 80-180 students from across the district, depending on what courses are being offered. Students learn numerous skills while absorbing the message that not everybody needs to go to a four-year university. Programs like Tools for the Trades and the rat rod build-off hit that lesson home even stronger. “They are seeing that you can make a living wage, and that there are plenty of jobs for people out there who are interested in the trades,” Humphrey says. “I think the kids are coming to realize that this is a viable option to have a successful life after high school.”

Overall, Humphrey and Kominski have seen excitement growing among students and their parents about the hands-on learning at Roosevelt High. Automotive students start with basics like fluid maintenance and then advance to working on steering, suspension, brakes, electrical systems, and engines and transmissions. Many branch into specialties like power sports engines, lawn mowers, and other advanced automotive work like collision repair and custom paint for vehicles.

“I think the stigma of the trades as something to fall back on or just for someone who is not high achieving is starting to dwindle,” Kominski says. “In all of our trades, the technology has advanced just like any other facet of life,” opening doors for people who like gaming or information technology to work on vehicles filled with computer modules. “Now parents are excited that their kids are interested in these classes.”

Wider paths to the trades

Getting more youth interested in skilled trades jobs is vital to communities across Minnesota. As Enterprise Minnesota President and CEO Bob Kill meets with manufacturers in cities big and small, he hears that hiring skilled and unskilled labor is still their most-pressing concern — though the pressure has eased a bit post-pandemic. “Community by community, it’s the number one issue,” Kill says. “It’s being able to find people with the right kinds of skills or the right kinds of aptitude to train them to help them grow their business.”

Tools for the Trades and other initiatives to interest people in hands-on careers are effective because they offer skills development and experiential learning. The benefit of companies like Northern Tool contributing to workforce development is that they can make a broader impact by targeting numerous communities at once. “What I like about a program like Tools for the Trades is they are putting money into it with professional-grade tools and instruction, and they are creating enthusiasm and success stories,” Kill says. “And that just breeds more success stories.”

It is also no secret that the program benefits Northern Tool as well. Broadening the overall population of professional tradespeople and serious do-it-yourselfers — who also associate the company with high-quality tools and a propensity for giving back — can only help expand its markets and customer base as it continues to grow.

And with Krishna at the helm, the company has big plans for growth. A board member since 2014 who became CEO in 2020, Krishna is leading Northern Tool on a plan to expand its footprint and $1.5 billion in annual revenue. While the company previously opened two to three stores a year, it is now on a quicker pace of opening five to eight stores annually. In the past three years, Northern Tool opened 25 new stores, often in its sweet spot of exurban locations close to metropolitan areas.

Other vehicles for growth include Northern Tool’s manufacturing wing that makes private label equipment and other products. It has 12 brands, such as NorthStar engines (the brand powering the rat rod go-karts), generators, and pressure washers, as well as Strongway jacks and lifts, Roughneck fuel pumps, and Klutch power tools. Its subsidiary, Great Northern Equipment (GNE), has grown into the largest Honda engine distributor in the country. GNE recently added distribution of Northern Tool’s manufactured products to other channels, including rental companies and independent retailers.

As a manufacturer, Northern Tool understands the challenges facing fellow manufacturers and the constant need for talented employees, Krishna says. “There are about 5 million jobs today that are trade-related or associated with trades that are not filled because there isn’t enough of a pipeline of students coming through with the right kind of training,” he adds. “This is our contribution to help communities have a pipeline of folks who do the tough jobs because they are the ones building the country.”

A program like Tools for the Trades is a natural fit for the company because giving back has always been part of its DNA, says Ryan Kotula, who co-owns Northern Tool with his brother, Wade. Their father, Don Kotula, grew up on the Iron Range working at his family’s scrap metal company. He started Northern Tool out of his home selling log splitters, hydraulic tools, and other parts, opening the first store in Burnsville in 1981.

The company has been an avid supporter of trades-based education, donating equipment to technical schools and community colleges for years. Tools for the Trades puts a new spin on those efforts by bringing other manufacturers onboard and focusing on high school students, Kotula says. Acknowledging that paths to the trades — industrial arts courses — just aren’t as available or funded as they used to be, the company wanted to do its part to entice more students to pursue these careers.

“This effort helps high school kids focus on trades and shows so it’s not just a secondary thought — it can be a primary thought and career path,” Kotula says. “If you’re not using the proper equipment, it can reduce your interest in doing an activity. We want to provide quality tools to get kids interested in doing it.”

The Kotula brothers believe that their father would have championed Tools for the Trades. He was a generous man who always looked out for other people, whether it was giving someone a job or helping them make connections. “He’d say, ‘We can’t help everyone, but we can help someone. And if everybody helped somebody, then things will get better,’” Kotula says. “We can’t solve all of the problems at once, but we can help other people get a leg up. Sometimes that means getting tools in the hands of kids and getting them interested in the trades, and that can change their whole career path.”

In social media interviews with some of the Lakeville and Minneapolis students, the encouragement to consider hands-on careers has been effective. A Minneapolis student talks about planning to go to trade school to focus on automotive, saying that “I like doing this so much that I want to do it for my job. I’m hoping that later on it will help me get into a more stable job, and a fun one at that.”

Another student mentions that she came to Lakeville North as a senior because of its CTE classes, not knowing about the rat rod competition. Calling it “the coolest thing ever,” she is grateful for the opportunity to get her feet wet in welding and explore automotive.

It’s been a joy for teachers Baas, Kominski, and Humphrey to watch their students get completely engrossed in building the go-karts. “You can read a book about rebuilding an engine and get a general idea of how to do it. But unless you use the tools and have done the hands-on aspect of it, you will never get that same experience,” Humphrey says.

“Tools for the Trades makes it easier for students to get their hands dirty and learn the topics we want to teach them,” he adds. “Northern Tool did an awesome job for us by providing tools and equipment that were on our wish list for years.”

Return to the Summer 2024 issue of Enterprise Minnesota® magazine.