In tiny Chatfield, Minn., population 2,900, a furniture manufacturer hums with activity as its 117 employees design and produce mid- to high-end contract office furniture. The company, which also has a 46-employee veneer plant in Wis., has a reputation for high quality products and on-time delivery. But two years ago, the management team saw a potential to improve even more through better communication, better development of employees, and a better process to achieve measurable daily results.

The company is Tuohy Furniture, and when Enterprise Minnesota reached out to see if its leaders wanted to participate in a pilot program for a business consulting service called Leading Daily for Results, the manufacturer jumped at the opportunity.

“We saw the benefits,” says Michael Tuohy, the company’s chief operating officer. “We knew there were opportunities there — for personal growth, for creating a better communication process — but we didn’t know exactly how to access them.”

Leading Daily for Results showed Tuohy and his team the way. In development for the past two years, the series combines lean thinking with leadership skills. The result is a communication process that aligns and connects a company’s strategic direction with daily improvements by employees to yield sustained results.

Through six half-day sessions, participants develop and implement a communication process specific to their company’s needs. By the end of the series, leaders will have developed, implemented, and tested a communication board and daily meeting routine that fuels this process.

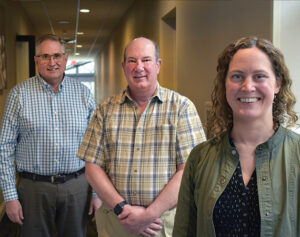

The pilot series was delivered by Enterprise Minnesota business growth consultants Abbey Hellickson and Greg Langfield, who have worked with manufacturing companies for years. Hellickson, with a background in leadership and talent development, advises leaders at all levels. With expertise in process improvement, Langfield helps companies do more with less through continuous improvement training and ISO certification consulting. Over years of conversations about their services and clients, Hellickson and Langfield identified an opportunity to offer their expertise jointly — a combination that yields benefits well beyond the value of independent consulting in their specific areas.

In the first step of the series, leaders identify the big “why” — their mission, vision, and values. Next, they learn to communicate that why to their employees. Then they develop measures to communicate “what is important” and to assess daily progress. The series also helps companies incorporate lean principles and helps participants learn how to coach employees to take small actions to improve their work areas.

“Skill development of leaders within manufacturing organizations requires the integration of process thinking along with the development of ‘essential’ skills to drive improved business performance,” says Langfield.

Hellickson adds, “The goal is for leaders to coach their employees to take small actions every day, through daily management of their work areas. These skills in leading through daily actions involve building processes around planning, communication and problem solving.”

Leadership communication

Hellickson typically begins the skill development sessions by asking leaders if they get the results they expect from their employees. Often, Hellickson says, companies find that the communication process they have in place fails to connect leaders and employees. The goal is to make sure communication is aligned from top to bottom. This can be accomplished by defining “what is important” in both words and actions — and recognizing that every action a leader takes communicates this as well.

Twin City EDM & Manufacturing Inc. is another company that gained from this emphasis on communication in the Leading Daily for Results pilot. Based in Fridley, Minn., the thriving manufacturer of complex precision medical and industrial components and devices has 90 employees. It recently doubled its facility size from 20,000 square feet to 40,000 square feet, runs two shifts Monday through Thursday, and another three-day, 36-hour shift on weekends to keep up with demand.

Like many Minnesota manufacturers, in recent years, Twin City EDM & Mfg. has faced challenges in the labor market just as demand for its products has exploded. With a diverse workforce, including immigrants with various backgrounds, the company’s vice president and chief executive officer Steve Lindell says it is important to convey the company’s core values and commitment to quality on a consistent basis.

Lindell and his management team used Leading Daily for Results to improve communication with area leaders and employees. “Continuous training and continuing to evolve our culture are huge parts of our success,” Lindell says.

Lindell and Twin City EDM & Mfg. launched daily meetings between area leaders and employees based on huddle boards that outline measurable goals and progress toward those goals (see The Huddle Board Defined, below). In addition to keeping the teams on track with respect to goals, Leading Daily for Results has brought the leadership team together with production floor employees consistently.

For Twin City EDM & Mfg. that means a weekly executive team walk-through with all area leaders. These walk-throughs, which take five to 10 minutes for each area, allow an ongoing opportunity for communication about the company’s core values and mission.

“It forces your hand to be consistent about the goals you have established because there you are in front of the group. We’re in a tough environment right now, so that’s needed — in a nice way,” says Lindell of the communication process created by daily and weekly management meetings.

Skill development

“Within any business, the role of leadership is to ensure needs are equally met in three areas: customer, business, and employees,” Langfield says. To keep that balance, the leadership team needs to communicate “what is important” every day, and then apply coaching skills to have employees take actions for improvement, he explains. “This is accomplished with daily conversations with employees based on a structured agenda.”

Hellickson, with expertise in growing leaders, adds that through Leading Daily for Results, her coaching has been enhanced by bringing in the data and measurement aspects Langfield shares with his clients. Manufacturers, she says, benefit more from a practical application of the skills she teaches. “In terms of leadership skills, we now have a venue. By blending these two together, the structure is easier to comprehend and digest and execute,” Hellickson says.

For Michael Tuohy and Tuohy Furniture, Leading Daily for Results has improved leadership skills across the company. “The entire executive team, literally, meets every Monday morning with each area or department on the production floor,” he says. “For five to 10 minutes, the lead in that production area will present his or her week, discuss critical points, what got done, and what didn’t get done. Then they have an opportunity to ask questions of us and tell us if there are things that we need to engage in to help.”

This type of scheduled, weekly checkup is new for the company, Tuohy says, and because of it, leadership skills across the company have grown. “Specific to the executive team, we have a deeper awareness of the processes and issues on the production floor,” he says.

The process has created a clear path of communication and defined the framework of the conversation. That, Tuohy says, has led to tremendous skill growth for the employees on the production floor. “Some of the lead people there — they know on a Monday morning they have to give a presentation. When you manage an area, you have to casually know things. But when you have to present, and you have to go over certain documents, and chart out progress, it formalizes it,” Tuohy says. “It also grows that individual as well.”

Langfield and Hellickson reiterate that skill development is dependent on employees understanding the “why” of the company. But area leaders and employees also need to understand measures, including how to define a good day, how to review a daily status, and how to transform that information into a call to action. Through Leading Daily for Results, participants learn about these steps and have an opportunity to practice actual situations from their companies.

“When employees are involved in daily problem solving, organizations grow and improve every day,” Hellickson says. “Employee engagement occurs when leaders embrace the use of measurements, communicate the story that the measurements tell, and coach employees to implement actions.”

Daily dialogue

Leading Daily for Results helps companies align their communication so employees understand the why — what drives the company. The skills developed through the series give leaders across the organization the tools they need to guide employees toward the company’s goals. Daily dialogue is the application of these tools and skills on a consistent basis to help employees win each day. It is the convergence of all the critical aspects of Leading Daily for Results.

Langfield explains that the foundation of the daily meeting involves telling a story, and that in that story, there are data and facts. The data are the measures that communicate the status of the goals. The facts are the stories behind the data. “The area leader needs to understand the facts behind the data to have an effective meeting. We have to find out what’s going on,” he says. “At the daily meeting we can talk about issues, about getting better, with a focus on the process, not the person.”

Hellickson adds that dialogue was critical during the pilot series. “Once they started to have things happen, and the leadership team supported them and took action as well, that was really the key,” she says. “Employees show up to be productive. If we tell them what’s important, they will respond.”

Daily huddle meetings — the core of Leading Daily for Results — reinforce what is important to the company, provide tools to assess progress toward those goals, and help employees engage in problem solving to address any areas where goals are not met. In the training sessions, area leaders are coached on how to conduct daily huddles; they also have the opportunity to practice leading them before guiding employees through them.

At Twin City EDM & Mfg., Lindell says the Leading Daily for Results training for area leaders was extensive. “They worked with them on how to do a meeting with people and how to present to management,” he explains.

Weekly meetings with management around the huddle board are essential. They provide both accountability and help to the teams working on improving their performance. The final session in Leading Daily for Results helps management develop the skills needed to guide these weekly meetings effectively. It also coaches managers on how to support area leaders working to improve their own leadership skills.

For both Lindell and Tuohy, the daily dialogue and weekly meetings have proven extremely beneficial. The area leaders at Tuohy Furniture manage the process. “They have, literally, on a board on the wall, performance areas they are tracking,” Tuohy says. “We review the previous week’s performance for each target and see if it’s green — accomplished — or red — an opportunity for action. If it’s red, there is an action plan.”

At Twin City EDM & Mfg., the management team has been doing the weekly walk-throughs for at least six months. “We’ve been involved since we started and haven’t missed one,” Lindell says of the huddle board sessions.

“Each week, five or six executives take part in the meetings,” Lindell continues. For each area, the sessions take 10 to 15 minutes; they cover what they are doing as a department that week and how they are progressing on what was suggested the previous week, he explains.

Lindell contrasts the daily and weekly sessions with how his company managed employee progress prior to Leading Daily for Results. “Before, you’d sit down with a manager for a review and you’d spell out expectations and then in six months you’d check on the review and find out you’re right where you started,” he says.

Lindell says his company has tried to get all employees cross-trained over the last several years, but progress has been stalled because it seems everyone runs out of time. One result of the daily and weekly sessions has been accountability toward the goal. “We have a plan in place, and we’re working through it,” he says.

Tuohy says the daily dialogue and weekly walk-through process allow managers to interact with all employees, not just the area leaders. “It also increases the engagement of the employees. They may be a little shy, but if they have the right place to offer a suggestion, they can do that, and they get all the accolades and support and the encouragement to try something for the company,” he explains.

“It’s great company-wise and good for business, but for that person, who might have been historically a little shy, it’s a big deal to mention something, have everyone talk about it and think through how to do it, and try it out,” Tuohy adds.

Overall, Tuohy says, the daily huddle meeting has really given Tuohy Furniture a boost. “It wasn’t that we had quality issues or growth issues. We had a good workforce and made changes to help make each day better with production scheduling improvements, for example,” he says. “But the daily huddle was new, and it has helped take a good company with good fundamentals and make it even better.”

The Huddle Board defined

“Think about a sports team that’s trying to win a game,” says Enterprise Minnesota business growth consultant Greg Langfield. “If there’s no scoreboard, how do you know if you are winning?”

The Leading Daily for Results skill development series integrates key areas around leadership communication involving measurement, goals, obstacles, and action to help companies win each day. A visual representation of the measures and progress toward winning the day, the huddle board serves as the scoreboard for the team.

While each team customizes its huddle board with goals and measurements, each one includes the same key categories, which are listed horizontally and start and end with employee-based measures: Safety, Quality, Delivery, Cost, and Employee Development.

For each category, daily progress toward the goals is marked in green or red. Green represents success in a category; red represents an opportunity for action. The measurements are placed in the center of the board, with the company’s vision, mission and values along the top, and a visual representation of the eight wastes of DOWNTIME along the bottom. The board, along with daily dialogue, provides the framework for employees to take small actions that will impact the measures to “win the day.”

…

Featured story in the Summer 2022 issue of Enterprise Minnesota magazine.