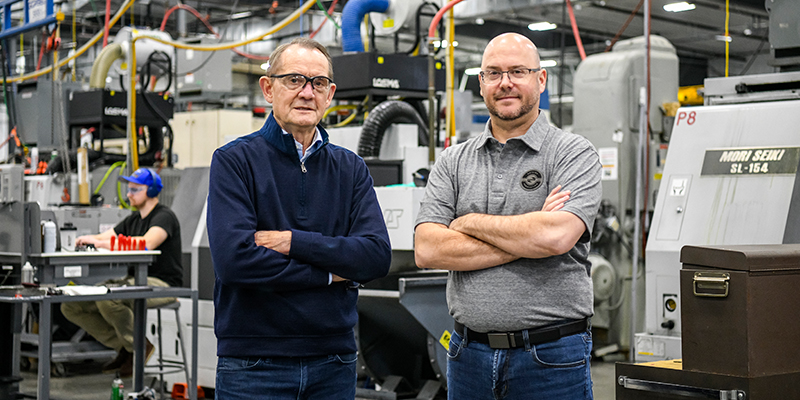

Bill Martinson has spent 35 years sharing his expertise with manufacturers, visiting their facilities, and identifying places where he can help them run better. A business development consultant for Enterprise Minnesota, Martinson brings deep know-how in the areas of engineering, operations, strategy, and more. And as well as manufacturers perform, Martinson usually finds some areas of opportunity for companies to fine-tune.

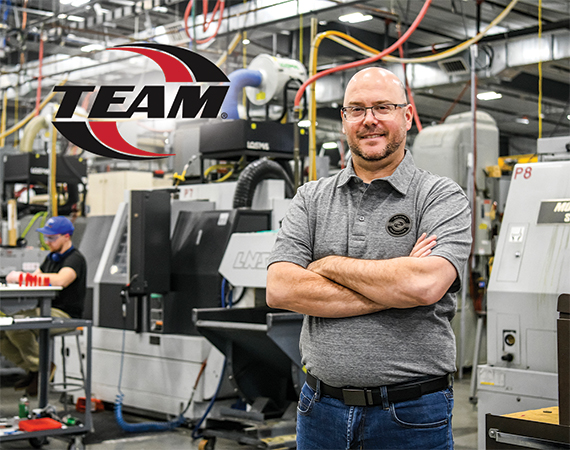

Yet upon visiting TEAM Industries in Bagley, Minn., Martinson was as surprised as anyone that he couldn’t find one aspect of the company that needed improvement. The third-generation manufacturer of drive-train technology for the power sports, lawn and garden, and light vehicle sectors, TEAM Industries hums under the leadership of president and CEO Micah Ricke. During the late 2024 visit, Martinson was blown away by the company’s automation, quality systems, lean processes, leadership, and culture.

Martinson and Enterprise Minnesota’s president and CEO Bob Kill agree — TEAM Industries ranks as the best-run company they have seen, with a star leader at the top. Ricke is “the best CEO I’ve seen. I’m sure there are other good ones out there, but I haven’t seen them. I’m impressed with the way he manages the company,” Martinson says.

What is it about TEAM Industries that makes it so outstanding? There are many puzzle pieces that fit together to explain why this nearly 60-year-old business is a model manufacturer. It all starts with the premise of the company, founded by Ricke’s grandparents, Don and Beatrice Ricke, as Motek Engineering and Manufacturing. They aimed to expand the Cambridge, Minn., machine shop by opening locations in rural communities like their hometowns in northwestern Minnesota. That way, people could have high-quality, professional and manufacturing jobs paired with access to the small-town Minnesota lifestyle they loved.

Over the years, TEAM Industries has built an employee-oriented, family-focused culture. Micah Ricke learned the business from doing machining as a teenager, getting experience at other manufacturers before and during college, and from his grandfather and father, David, who preceded him as CEO. Their central teachings include uniting as a team to solve steep challenges — good or bad — and forging deep relationships with customers built on responsiveness and collaboration. TEAM Industries cultivates a loyal and engaged staff by promoting from within and providing a stake through its employee stock ownership plan (ESOP).

Since becoming president and CEO in 2023, Ricke has been building upon the foundation of success started and strengthened by his predecessors and hundreds of employees over the years. But he’s putting his own stamp on TEAM Industries by focusing on forecasting and goal planning, diversifying its business lines, and improving cross-company communication. Ricke is striving to set the company up for longevity by fostering a growth mentality across the board to steer it toward an even brighter future. “If you’re not growing, you’re dying. That saying used to rub a lot of people the wrong way, but I’m not just talking about sales. I’m talking about everything. Improving yourselves, improving your processes, growth in capabilities, expertise, culture –– you want everything headed in a growth direction,” he says. “To me, trying to figure out how to take on more work is a good problem.”

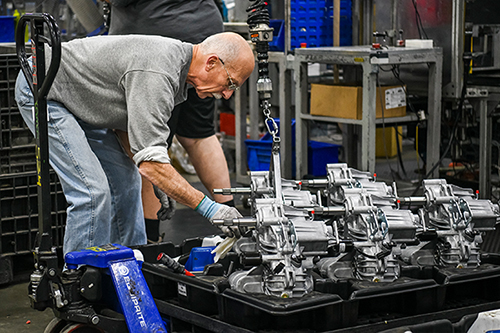

Today, TEAM Industries has nearly 1,200 employees, including 800 in Minnesota. It operates five facilities in the North Star State, one in North Carolina, and two in Mexico. Combined, the company’s workforce is united behind a mission to serve as the manufacturer of choice for OEM customers in need of sophisticated, efficient power for their products. Its one-stop design, engineering, and manufacturing services –– and commitment to anticipating and meeting customers’ needs –– have kept TEAM Industries at the top of the roster for companies in numerous industries, from power sports and marine to agriculture and construction.

Ricke has many assets to build upon, along with pillars that make TEAM Industries a successful manufacturer. Based on the observations of Ricke, four TEAM senior leaders, plus Martinson and Kill, here are the four key attributes that make the company stand out.

1) Starting at the top

TEAM is off to the races with a strong new leader in Ricke. He’s adopted a fresh approach to running the manufacturing business, including using sophisticated forecasting and sales projection tools to guide decision-making, the likes Martinson hasn’t seen before. Kill is impressed with Ricke’s management style and focus on using outside data to set a course for the business.

“TEAM Industries as a company has a really great reputation in the world. It’s a great place to work in rural communities –– and that’s a reflection of the family,” Kill says. In meeting Ricke, “I was struck immediately by how thoughtful he is in his role as president and CEO. He’s bringing metrics and goals and planning to the organization to minimize the downs and better manage the ups.”

Sue O’Brien, director of supply chain who has been with TEAM Industries since 2000, noticed a shift when Ricke took the helm. Previously, the leadership approach was more hands-off. Now with the third generation assuming more responsibility, O’Brien sees the company embracing a different style. She points to Ricke championing the Entrepreneurial Operating System (EOS). Aiming to concentrate more intentionally on planning and achieving goals, TEAM Industries launched EOS with its executive leadership group in 2024 and is rolling it out companywide this year.

It’s something Ricke wanted to do for years to increase accountability toward meeting objectives. He views EOS as an effective tool for involving employees in tackling big-picture challenges and communicating on a regular cadence with its staff companywide.

Ricke appreciates the EOS view of collaboration and teamwork. Instead of working in silos, employees work in sandboxes where they can pitch in when co-workers need help. “We’re creating a culture where we have a shared vision and passion for that vision, and then you want to set clearly defined and attainable goals, and then communicate, communicate, communicate,” Ricke says. “EOS gives us the tools for that. We’re promoting a sense of entrepreneurship and really getting people to see that if you need help, there are lots of people here who are willing to help. Having a system like this helps employees feel like they are owners and know what’s going on.”

O’Brien finds the EOS focus on teamwork and planning refreshing, especially its emphasis on shared values, working together to meet common goals, and ramping up communication. She has been deploying the EOS process to her supply chain group. Even though it has added to her workload with some critical projects, “I am so excited about the future. My department is excited because they know these are the right things to do for the company,” O’Brien adds. “Everybody wants to help build us back up and have a great future. It’s really exciting to see and be a part of.”

CFO Chad Armstrong sees strength in Ricke as a leader who is guiding a company through the transition to its third generation — not always an easy feat. Coalescing employees around EOS initiatives, with its focus on empowering leaders and improving processes, will set both Ricke and TEAM Industries up for further success.

“The goal coming out of adopting the EOS system is having a company that has even more communication and more joint decision-making with all the facilities,” Armstrong adds. “It’s bringing the company up to the next level.”

2) Employee experience

Talk to a TEAM Industries employee and it’s highly likely that they have worked at the company for years. TEAM’s workforce is a key contributor to its longevity and success. Employees regularly start in entry-level positions and work their way up after showing initiative and a willingness to learn.

“My first and foremost core value is prioritizing employees –– happy employees will lead to happy customers,” Ricke says. Employees own 40% of the company through TEAM’s ESOP, helping to retain its workforce and giving employees a big stake in its success. “I want employees to feel like they are owners, too. In my opinion, they have just as much say in how things go as the family does.”

Director of Manufacturing Mike Olson joined TEAM Industries in 1995 as a night shift operator at its Audubon plant. Over the years, he turned down outside opportunities because of TEAM’s culture and employee experience. He appreciates being able to continue living in the area where he grew up, with a great job at a private company. To Olson, that means leaders make decisions for the right reasons to benefit TEAM and its people, not necessarily the wishes of the stock market.

Employees also stay for the long haul because the company stresses providing training and promoting from within. “TEAM has many long-term employees, and when you work with people for 30 years, you feel like you are family,” Olson says. This sensibility leads to a propensity for collaboration and an ability to pick up the phone to make decisions. “You know the people on the other end, you trust the people on the other end, and you know they have your back.”

Even though employees are spread across multiple locations, the company’s workforce is close-knit, says Ron Wendt, director of product development. It’s something he noticed from 17 years working at TEAM, with a four-year break at a Twin Cities manufacturer before returning in 2011. “I love the way our workforce pulls together and understands that times might be tough sometimes,” Wendt says. “We act like one big workforce, and the Ricke family takes a long-term approach to make sure TEAM is successful.”

Adding to the family feel is the workforce’s palpable excitement for TEAM’s products, Wendt says. It’s a crowd that uses the snowmobiles, ATVs, and side-by-sides made with TEAM’s drivetrains, axles, differentials and other components. Backing up that passion is employees’ willingness to roll up their sleeves and get their hands dirty in search of solutions.

“We understand what we want to see in the products because we use the products,” Wendt adds. “What separates us from the competition is that we understand the needs of the vehicle, and we’re looking deeper at how different decisions will affect the vehicle.”

3) Collaboration and risk-taking

When employees work together for decades, it builds up a base level of trust that fosters comfort with advocating for innovative ideas and teamwork, Olson observes. For example, there is a strong, cohesive working relationship between the design and manufacturing departments that he attributes to employees’ longevity.

“I think TEAM is very innovative with design and has been since day one. We are able to provide a product that has good cost out of the gate because everyone teams up on multiple iterations to eliminate costs before the start of production,” Olson says.

TEAM Industries also fosters and supports employees’ creativity. When employees have product or design ideas, managers will often provide seed funding and time to prove out their concepts, Wendt says. It serves as a way to keep employees productive during slower times and continue offering cutting-edge technology.

Wendt points to TEAM’s Smart Locker component, an intelligent front drive that locks or unlocks traction control based on terrain. An engineer sought an element for his own vehicle and started developing the technology. The team kept iterating and testing, ultimately leading to a customer incorporating Smart Locker into their product line. TEAM provided the time and seed funding over a decade until it became a highly successful offering for customers.

Armstrong, a relatively new kid on the block who joined TEAM Industries just before COVID hit, brings experience from several other manufacturers. He’s noticed a distinctive culture of trust emanating from the top that empowers employees and unleashes their creativity. “They really believe in the people they hire. They pay close attention to who they hire, but if you make it through that gate, you’re in that circle of trust,” Armstrong says. “It takes the lid off for capacity and growth and leads to innovation. Believing in employees gives them an ownership mentality, too.”

4) Deepening diversification and efficiency

Other hallmarks of TEAM that help it thrive include its model of vertical integration, commitment to automation, and ability to serve multiple markets with a wide array of products and services. That’s the beauty of having eight plants with different focus areas. Being situated in rural locations allows TEAM to attract high-caliber employees with expertise in various specialties, including engineering, high-speed machining of aluminum or castings, gearing, hydraulics, and assembly.

The plants put products in close reach of customers, who might have manufacturing facilities clustered in specific areas. For example, TEAM’s two facilities near Monterrey, Mexico seamlessly supply OEMs that make products in the United States and Mexico with the same components. “We have the different plants for diversification,” Ricke says. “It gives you access to different regions and different concentrations of customers and suppliers.”

Having diversified services also provides opportunities for TEAM to apply its capabilities in new areas. This is a priority for Ricke, who has experienced several boom-and-bust periods in TEAM’s power sports and recreation lines. That includes 2024’s 20-25% drop in sales after the pandemic boom, inflation, and high interest rates. Ricke and team are calling on the expertise of different plants to expand its business in sectors like aerospace, heavy trucking, green energy, and industries that are electrifying their products.

TEAM Industries stays efficient and highly productive by regularly championing automation, lean operations, and continuous improvement, Olson says. These aren’t one-off projects but work that is strategically planned for all of the company’s locations. Such efforts, combined with its vertical integration, help the company stay nimble and provide customers with a good value, Ricke says.

Wendt finds that product development especially benefits from TEAM’s vertical integration. “It allows us in product design to work hand-in-hand with the manufacturing staff and find the most efficient way to design something. We do that on the front-end to maximize cost, reliability, and durability –– you don’t find that in a lot of companies,” Wendt says. “Having all of that expertise in-house really allows us to focus on that.”

Automation has always played a big role at TEAM, from Olson’s early years at the company when he became the first operator to run a robot in the early 2000s. Staying on top of automation technology has helped the company stay efficient. He cites TEAM’s Audubon plant, where about 160 people today produce the same quantities as the 300 employees who worked there in the mid-2000s. Thanks to TEAM’s corporate automation group, robots load and unload 50 parts an hour, freeing up operators to oversee 20 machines instead of being stationed all day at one piece of equipment.

It’s all a testament to TEAM’s propensity to invest in the elements that will support its chief goals, Ricke says: providing customers with high-quality components, being nimble and responsive to their needs, and collaborating to solve the challenges they might have.

Return to the Spring 2025 issue of Enterprise Minnesota® magazine.