At the time, the population of Holdingford — which sits 25 miles northwest of St. Cloud — had a modest population that hovered around 500 people. But it was big enough for a blacksmith shop, so Vince, Roy, and Frank Warzecha set up shop a few miles outside of town.

It was here where the Warzecha name became synonymous with metals in the Holdingford area. While the blacksmith shop may be long gone, the Warzecha name has remained important in Holdingford. Today, 80 years after the doors opened on that blacksmith shop, the Warzecha name remains at the head of one of the town’s most successful businesses.

Two Rivers Enterprises, a top manufacturer of food processing equipment, employs about 50 people at its facility, which sits 90 minutes northwest of the Twin Cities.

Two Rivers’ deep roots don’t mean it’s rooted in the ways of the past. While it leans into the history of hard work and rural Minnesota values, the company is planning for a cutting-edge future that emphasizes efficiency, productivity, and profitability. Doing so, company leaders say, will help them stick around another 80 years and more.

“When Jessica Wells and I started in the business five years ago, there wasn’t a plan in place, and there wasn’t a direction, the goals weren’t clear,” Two Rivers President Brian Warzecha says. “We wanted a plan that addressed not just where we want to go as a business in terms of revenue and dollars and profitability, but one that also addressed goals for our employees, expectations, culture — we had to tackle things that the business was missing.”

Enterprise Minnesota would help them hone and refine their strategic planning process poised for sustained growth.

Food

Today Two Rivers Enterprises is a custom stainless steel equipment fabricator for food processing, foodservice, restaurants, pharmacies, and medical practices. But it took a lengthy route to get there.

Frank’s sons Bob and Dan worked at Lake State Industries until 1999 when they came to Holdingford to set up a new business. While Two Rivers initially split its output at roughly 95% for restaurant equipment and 5% for food processing equipment, that ratio today is exactly the opposite.

This strategic shift represents a key driver of Two Rivers’ growth and transformation.

Two Rivers tries to work with as many local companies as possible. Keeping things local — and domestic — is a source of pride for them.

Diversifying into custom food processing

Visitors who step inside Two Rivers’ bustling facility quickly see the sheer diversity of their product offerings; conveyors, custom food processing equipment, sous vide cook systems (which cook food at low temperatures), steam ovens, mezzanine platforms, conveyors — the list goes on.

“When our team goes into a food plant, it’s our goal to make our customers’ equipment needs a reality,” Warzecha says.

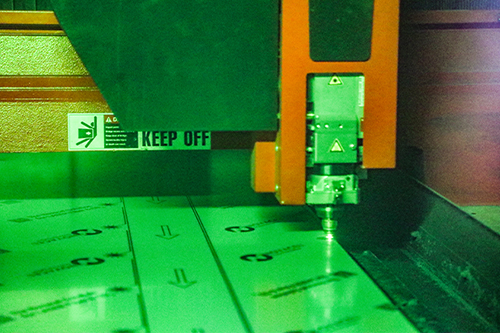

During a tour, General Manager Jessica Wells calls attention to the company’s newest showpiece, a state-of-the-art water jet cutter, installed just a week earlier. The machine can slice through metal with precision and speed. Unlike older models, the new machine submerges the workpiece in a tank of water about the size of a parking stall. With the old machine, Wells says the sound was loud enough to leave workers reaching for ear plugs. The new one creates a “remarkably quiet and clean” work environment.

The water jet represents a broader push toward automation that is transforming this manufacturer’s processes.

In another area of the plant, Wells shows off the Time Saver machine, a specialized piece of equipment that uses a vacuum bed and rotating sandpaper discs to deburr and smooth the edges of freshly cut parts. Cut steel parts usually retain a few shards that must be removed.

Rather than tedious manual work, this automated system can process an entire batch in just a few hours.

“It’s kind of like sandpaper,” says Wells.

When done manually, each part can take several minutes. The aptly named Time Saver can deburr dozens of parts at once.

On this machine, Two Rivers partnered with students in St. Cloud State University’s engineering department, who created an adjustable table with rollers that catch and flow the deburred parts.

A few feet away, a state-of-the-art CNC router handles plastic fabrication needs, replacing outdated tools and outsourced work. And in the welding department, a custom-built seam welder ensures a consistent, high-quality finish on their stainless-steel sinks and countertops.

In 2023, the company invested in a CNC cutting laser. This investment took their daily cutting from 15-18 hours a day down to five hours daily. It allowed them to reposition employees to better support the needs of the business.

By embracing automation and innovation, Two Rivers aims to position itself for continued growth.

This custom approach is central to Two Rivers’ success. Rather than relying on off-the-shelf solutions, the company’s team of nine engineers works closely with customers to bring clients’ ideas to life.

“We take our customers’ ideas, and we try to make them a reality,” Warzecha says.

The company’s vast library of past projects provides a solid foundation, but each new solution requires a fresh approach.

“A conveyor is a conveyor, it has rollers, it has a drive, a gearbox, and it spins a belt. But the footprint is custom,” Warzecha says. “So that’s where you have to reinvent the wheel.”

This custom focus has enabled Two Rivers to serve a diverse array of clients, including producers of beef, poultry, pork, confectionary, and dairy products, by designing and building specialized conveyance systems and cutting equipment.

“There are many different aspects of what we can do,” Warzecha says. “It’s what keeps us busy.”

Strategic planning, continuous improvement

While Two Rivers’ custom capabilities have been a key strength, the company recognized it needed to take a more strategic approach to unlock its potential. This realization led them to connect with experts who could help.

Working closely with business growth consultants at Enterprise Minnesota, the Two Rivers team embarked on a comprehensive strategic planning process that took nearly a year to complete. Warzecha says the results were transformative, as the company set clear goals and developed a roadmap to achieve them.

Warzecha says that, once they assembled a board of directors, they needed a strategic plan to help them progress from a company with steady growth to one with substantial growth. Now, a few years later, revenue is nearly three times what it was prior to the strategic plan’s implementation.

“When our board of directors came together, we said, ‘Okay, now we’ve got to start focusing on this plan,’” Warzecha recalls.

Mapping out a plan for growth and sticking to it has paid off.

Wells says that, when she and Warzecha started, Two Rivers had developed core values and a mission statement, although they were not formally launched.

“So that was kind of perfect timing for us, to work with our strategic plan to figure out what our goals are for one year, three years, 10 years,” Wells says, “and then start working on those initiatives to start building the business.”

In addition to the strategic planning, Two Rivers has also leveraged Enterprise Minnesota’s expertise in lean manufacturing and continuous improvement. The company has invested in a range of automation and technology solutions, from that time-saving deburring machine to the water jet and laser cutter. Both have dramatically improved efficiency and throughput.

“We were cutting on two shifts 15 to 18 hours a day,” Wells says. “Now we’re cutting five, six hours a day with two people.”

Expansion

As Two Rivers has grown, the company has recognized the need to expand its physical footprint. The company is currently in the midst of an expansion project, adding 10,000 square feet to its existing facility. This expansion will enable the company to optimize its manufacturing flow, with raw materials flowing seamlessly from cutting to deburring, pressing, and welding.

The expansion will include additional workspace and new equipment layouts to improve efficiency and flow, Wells says. “We’re planning to add an additional five to six welders.”

Two Rivers financed the expansion through state-level support programs, including the Minnesota Investment Fund (MIF) and the Job Creation Fund (JCF). These initiatives have provided low-interest loans and rebates, helping the company offset the costs of its growth.

Two Rivers is potentially getting a combined $320,000 from the JCF and MIF programs.

“The Job Creation Fund is basically like a rebate after you create the job,” Wells says. “The Minnesota Investment Fund is for equipment. So based on the equipment — we put in the water jet — the state will loan the city money at a low interest rate that it can then loan to the manufacturer.”

Beyond the physical expansion, Two Rivers has also invested heavily in its workforce. The company has forged partnerships with local high schools and St. Cloud State University, creating apprenticeship and internship programs to develop the next generation of skilled workers.

To further attract and retain top talent, Two Rivers offers a robust benefits package, including 100% coverage of employee health insurance, 401(k) matching, and competitive bonuses. The company also shares its profits with employees through an annual profit-sharing program.

“We do a competitive bonus. We do profit sharing. These are just other areas where we feel you’ve got to reward your team for the work that they’re doing,” Warzecha explains.

Industry insights

Two Rivers also recognizes the value of tapping into industry insights and networking opportunities. Through its participation in Enterprise Minnesota’s Peer Councils, company leaders say they have gained valuable perspectives on legislative changes, workforce policies, and best practices in areas such as AI and manufacturing.

Wells says she also gained insight into the ISO process, which validated Two Rivers’ decision to wait on pursuing an ISO registration.

“We were talking about this yesterday at my peer council,” says Wells. “If you are making any government, military type of stuff, then that’s where they’re looking to be ISO certified.”

Peer Council discussions have also informed the company’s approach to issues like employee bonuses, training, and continuous improvement.

Return to the Spring 2025 issue of Enterprise Minnesota® magazine.