Folks at Van Technologies Inc., a maker of environmentally friendly coatings, know that earning an ISO certification is not like completing a race. Rather, it’s more like lining up for a marathon.

The Duluth-based company obtained its ISO certification in near-record speed a few years ago, achieving the credential in less than half the eight to 10 months companies typically require, according to Keith Gadacz, a business development consultant for Enterprise Minnesota.

But Larry Van Iseghem — the company’s president, CEO and namesake — says his team continues to build on that platform of accountability, in order to drive performance and maintain ISO accreditation well into the future.

“I can see a definitive difference pre-ISO 9001 and post-ISO. I believe our operations are more efficient, which makes us much more cost-effective,” he says.

Since 2019, Van Technologies has boosted its output by 34%. And perhaps even more impressive is the fact that it has done so without adding much staff, as its production per labor hour has jumped by more than one-third since the pandemic disruption in 2020.

Gadacz says the strides in productivity are a testament to the work Van Technologies has put into improving its operations.

“I’m impressed that they can deliver the same quality products and more output with less labor per unit. That’s really what everyone wants to be after,” he says.

Van Iseghem strongly believes the ISO system the company adopted has strengthened an already-robust operation.

“We’ve always maintained a high-quality product, but with the procedural formalities and the adherence to procedures we’ve now adopted, I know, person to person, testing is done much more consistently and accurately,” Van Iseghem says.

Teresa Donahue, the company’s technical manager, agrees. “Having all the documentation and procedures in place has served us well. We did have a good basis prior to getting certified, but everything kind of came together when we developed this quality management system.”

Staff’s confidence in the unwavering quality of Van Technologies’ products, she says, has only grown with additional calibration and verification procedures.

“Having all of our employees engaged in this process and our quality objectives has created more of a team environment,” Donahue says.

Van Iseghem recalls that some clients and employees initially questioned the need for the ISO certification. “They asked: ‘Isn’t this expensive? Isn’t this a waste of time?’”

When COVID forced many people to pause day-to-day activities in 2020, Van Technologies saw its sales slip. Nevertheless, Van Iseghem says the company managed to recover later that year and eke out a small sales increase.

Van Technologies took advantage of the momentary lull to seek ISO certification.

“We were so close to it anyway, why not?” he recalls thinking. “The procedures we instituted in previous years and the attention we paid to detail were very consistent with ISO 9001.”

Van Iseghem launched his coatings company in 1991, shortly after leaving Ikonics, another Duluth-based company, where he had led a successful ISO-certification effort. So, many of the goals of the quality-control program already were ingrained in his thinking about how to run a successful business.

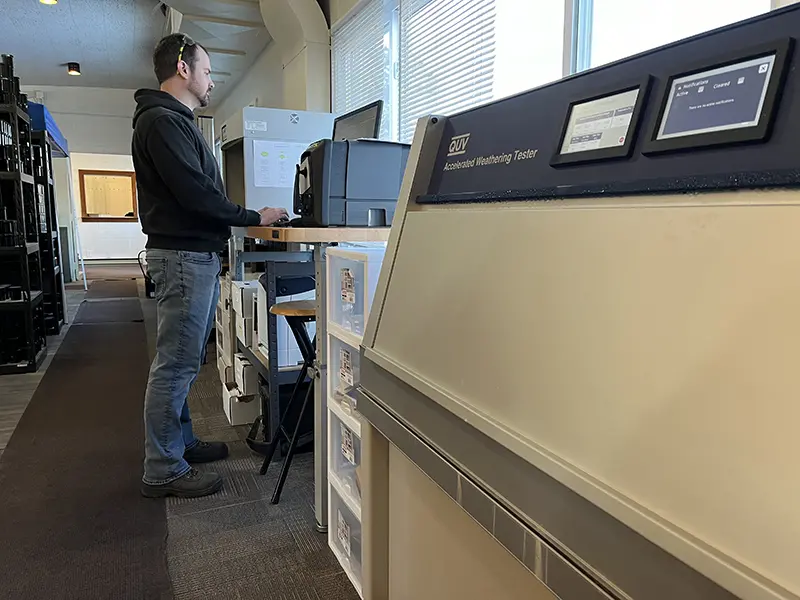

Van Technologies has distinguished itself not only for the quality of its coatings but also for its environmental advantages, with no solvent-based products in its lineup. Rather, the company focuses on specialized water-based coatings and products that can be quickly cured with ultraviolet light.

Van Iseghem says he also recognized the value of the credential.

“It certified to present and future customers our capabilities, our efficiencies, and our attention to detail,” he says.

“But the benefits I see and that I knew would come are in terms of our operational efficiency gains,” Van Iseghem says. “We’ve saved money by doing this.”

“So, everybody’s on board now. But there were a lot of questions from the onset, even from our vendor relationships. Our vendors view us differently today than they did pre-ISO, because they know that at Van Technologies, we’re going to pay attention to the products we buy from them. And that means they can do a better job,” he says.

An annual audit by an external third party is required to maintain an ISO certification.

But Van Technologies conducts three additional internal audits each year, and Van Iseghem tapped Gadacz to perform them.

“He’s very thorough and effective, plus he’s a good coach,” Van Iseghem says. “Our people know Keith is going to conduct a thorough audit. So, the attention to doing things correctly according to procedure is heightened. The internal audits are a good reminder and maintenance tool to continue to do things the right way.”

Van Technologies’ continued embrace of scrutiny serves the company well, according to Gadacz.

“They’re probably one of the strongest proponents of using outside eyes to help keep them sharper, stronger and faster,” Gadacz says.

Van Iseghem sings the benefits of continued vigilance.

“You just can’t get certified and leave it. After you get certified, you have to do your audits. I think our internal audits have been essential to maintain the program. And if you maintain the program, it returns the benefits you seek,” he says.

With the exception of 2020, Van Technologies has consistently grown its sales at a double-digit annual clip, according to Van Iseghem.

Van Technologies does not produce commodity coatings, such as those available at home-improvement stores. Instead, it serves customers with special needs, mostly in the high-end window market. But the company continues to diversify into other areas, including hardwood flooring, retail display fixtures, architectural millwork and doors, kitchen cabinetry, and other wood products.

Its product niche makes the company generally less susceptible to the vagaries of the economy than others in the housing industry.

“When money is tight those that continue to build are the individuals who have the money to do so. And we’re typically involved with the higher end of the market, which tends to be a little more stable than your lower-income housing,” he explains.

Van Technologies continues to seek new opportunities, with an eye toward volume.

Case in point: The company has developed a UV-cured product that is a durable coating for the flooring installed in most semi-trailer trucks.

“When you look at the number of semis on the highway, that’s a very attractive surface area market,” Van Iseghem says.

Van Technologies prides itself on providing coatings specifically tailored to a client’s needs.

“Our business model is: We solve problems. If you’ve got a problem, we’ll help you solve it, if it’s related to the coating industry,” Van Iseghem says.

With that reputation, Van Technologies has not had to be particularly aggressive on the sales and marketing front. Van Iseghem says much of the company’s business comes from referrals.

Increased product demand has Van Technologies shooting to hire an additional chemist and likely needing to physically expand in the near future. At present the company has about 18,100 square feet of production space and 5,200 square feet in another building that houses its offices and lab operations.

Donahue expects to add three or four employees to the 17 already on the company payroll.

Return to the Spring 2024 issue of Enterprise Minnesota® magazine.