Ally Johnston helps manufacturers improve productivity, eliminate waste and build a culture of continuous improvement. Prior to joining Enterprise Minnesota, Ally served as industrial engineer, quality systems manager, and operations manager for Genesis Attachments in Superior, Wis. She earned a B.S. in industrial engineering from the University of Minnesota-Duluth. Learn more about Ally and watch her video here.

Many employers face the twin challenges of an unprecedented worker shortage and unrelenting customer demand for on-time, high-quality production. Fortunately, there is a successful strategy to address both issues at the same time: initiate, or ramp up, company-wide continuous improvement programs.

To instill an environment for authentic, meaningful engagement with employees, managers must give them the skills and authority to recognize and initiate process improvement. Highly engaged employees contribute to a thriving company atmosphere. A Gallup survey recently reported that companies in the top 25% for high employee engagement perform much better in measures ranging from quality defects to profitability.

When instituting process improvements, leaders who embrace manageable, daily process improvements in short time will see happier employees as well as quality improvements and waste reduction. Notably, they don’t have to dedicate one staff person to the effort, or funnel substantial time and resources to a big one-time event.

A great work environment

It’s no surprise the worker shortage crisis has inspired manufacturing executives to focus on employee satisfaction. “Attracting and retaining a quality workforce” has never been a higher concern in the 13-year history of Enterprise Minnesota’s State of Manufacturing® survey of executives. Half of respondents say it is a challenge to doing business; half also report hiring new employees is the most important driver for future growth. The number of executives who now prioritize their work environment jumped from 39% to 69% from 2020 to 2021. These leaders realize a great work environment improves employee engagement, which is where lean and continuous improvement efforts can create such value.

Fueling employee engagement

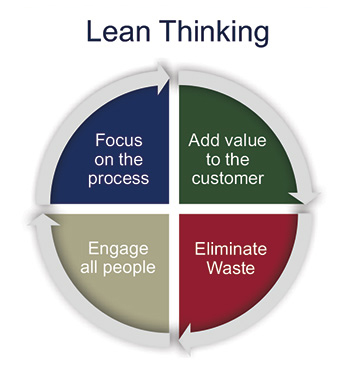

For leaders just embarking on one or both efforts, it is important to provide a fundamental understanding of the goals and processes of lean and continuous improvement. Lean is essentially a dynamic way to produce more product using the fewest resources. Continuous improvement, on the other hand, means ongoing positive change to all phases of an operation.

Continuous improvement done well is a constant effort that changes the way people work, the way people think, the processes they use, and the capability of an operation. Lean companies always have continuous improvement, but companies need not be lean to practice continuous improvement.

With lean and/or continuous improvement processes in place, employees are engaged at an authentic and high level. They are tasked to evaluate and improve the company’s processes daily. They are empowered to make bold suggestions and try new things. And — this is a crucial aspect of process improvement — they are allowed to try and fail, and try again, always working to improve outcomes.

Engagement at this high level gives companies a profound competitive advantage. The Gallup Workplace Survey, which tracks engagement in more than 100,000 business units across the U.S., shows just 36% of employees say they are engaged in their work. Engaged employees report they are passionate about striving for company goals. They are more productive, willing to recommend their employer to others, and satisfied with their home and personal lives. In terms of measurable outcomes, companies in the top 25% of engaged employees report 64% fewer safety incidents and 41% quality defects, with 81% less absenteeism. These same companies report 14% greater productivity and 23% greater profitability than those that measure below them in engagement.

All companies can see dramatic improvement in employee satisfaction by implementing or reinvigorating the process changes centered on lean and continuous improvement. After all, when employees feel they are contributing in a significant way to their employer’s success and ongoing improvement, they feel more connected to the company and motivated to initiate positive changes.

Beyond clock-in, clock-out

Consider a firm of about 50 employees that takes on steel fabrication projects for agriculture, construction and heavy equipment manufacturers. Morale and continuous improvement had stalled, and the company needed a boost.

The company implemented Lean Daily Management, a system that enables the organization to track their success at achieving goals. Training in Lean Daily Management helps employees identify process problems, take corrective action and check that past actions and improvements are being sustained.

After a successful pilot program, managers launched Lean Daily Management throughout the organization. It impacted one employee profoundly. This individual was a clock-in, clock-out kind of person, not engaged and he would even avoid eye contact. When he started seeing changes and improvements to processes that had frustrated him for years, he became a leader on the shop floor. It transformed his attitude. Not only did his engagement improve but so did the engagement of the team members around him.

Making great companies even better

By employing process improvement initiatives, the steel fabrication company reaped the benefits of improved morale and greater employee engagement. Those same initiatives — at the very same time — boost quality and reduce waste, a clear win for companies and their customers.

Another example is a very successful company that produces hydraulic scrap shears and concrete pulverizers for the recycling and demolition industry. Once the company gave its employees the tools to evaluate processes, it became even better.

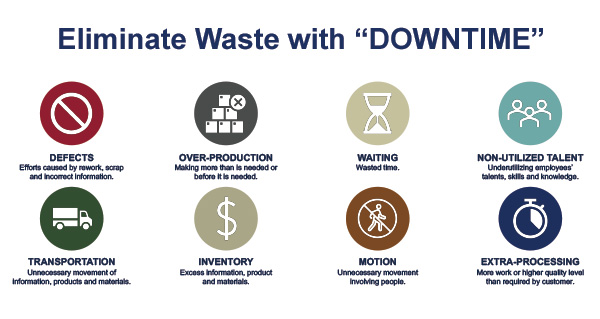

In one particular process, the company spent about 15 to 20 minutes welding a stop piece for a rotation swivel. It was a frustrating task for the employee assigned to the process because the tight space in which he worked made it difficult to weld. After the employee was trained in lean thinking — specifically in identifying waste — he suggested the welding be done in another area, earlier in the process. Acting on his recommendation, the company moved the welding task to a cell earlier in the process, saving five to 10 minutes in each production cycle.

Once the initial suggestion was made, the team evaluated further and determined it was over processing waste. They came to learn that employees at a sister company immediately removed the part when they received it, and then they welded in their own part that matched the design of their swivel.

The company went from performing a frustrating, 15-minute job for a decade to removing that job from the entire process. Absolutely, by engaging employees and giving them tools to evaluate problems and make changes, the results can be dramatic. Think of the impact of saving 15 minutes during each production cycle, compounded over 10 years!

Focus on process

Leaders of the most successful lean and continuous improvement cultures recognize the two-way street needed for these initiatives to take root and thrive. Managers cannot expect employees to think of ideas and bring them to company leadership if they are not given the knowledge, education, and opportunity to do so.

It’s important to take a step back and ask, “Am I developing my employees? Am I giving them an opportunity to suggest ideas? Am I empowering them? Am I letting them take initiative?”

Successful companies focus on processes — not individuals or departments — and make sure they are integrated throughout the company. From those processes, companies build systems that can address risk, change and growth. Systems improve constantly if everyone shares a passion for evaluating processes and then implementing improvements.

An 80-person manufacturing client of Enterprise Minnesota shows how empowering employees to recognize the potential for process improvement can yield enormous benefits. This company, which manufactures a variety of aluminum products, including ice houses, trailers and docks, brought in consultants from Enterprise Minnesota to train employees on Learn-to-See and DOWNTIME — two processes for identifying and minimizing or eliminating waste.

The employees learned the eight wastes of DOWNTIME and then went out on the floor to identify them. They learned daily management principles and had to identify a goal every single day and measure their progress toward the goal. Their continuous improvement culture was really taking hold.

A production lead took the information from these sessions and sat down with the scheduling lead to address a wasteful system that had been in place for years. Translating sales orders into a production schedule generated a mountain of paperwork and expended unquantifiable time — all just to get production started.

These two worked together using the principles they had learned to identify and eliminate waste. They trimmed the complex weekly scheduling document from 14 pages to a one-page instruction sheet. It made assigning floor tasks more straightforward for everyone on the team, reducing hours spent preparing and deciphering the complex instructions. The new process also meant the production lead could feel more comfortable taking vacation, knowing others could manage the process in his absence.

Fail fast, fail cheap, learn lots

This same company is currently working to improve its efficiency in aluminum trailer production. Every day the team has a goal of trailers built, and they are tracking daily to measure their progress. While evaluating their productivity, they’ve discovered they spend an excessive amount of time setting up to produce each trailer.

They have not yet found a solution to this challenge, but instead of jumping at the first idea — one that would be costly and might not help that much given their space constraints — they are now considering other possible solutions. Their engaged employees are rising to the challenge. One proposal suggests creating a fire-drill type fixture team that would be tasked with rapid set-up for production. In situations like this, where a team sees several potential solutions, it’s best to fail fast, fail cheap and learn lots. In other words, it often makes the most sense to try options that don’t involve big expenditures or lengthy implementation periods.

Regardless of what changes they try, this company is truly embracing the culture of continuous improvement by teaching employees how to see waste, empowering them to find solutions, and giving them the opportunity to try those solutions.

Making lean and continuous improvement work for your company

Companies that embrace continuous improvement and lean initiatives hold an advantage as they compete for both employees and customers. But leaders often say one of the biggest obstacles to implementing or enhancing their lean and continuous improvement processes is time.

Many report that lean and continuous improvement lose priority status when things get busy. This might be because many leaders see time-consuming events or dedicated managers as essential to these systematic process improvements. Assigning one manager to be the “Lean Person,” or having a few one-time events without following through to incorporate the skills learned into the workplace, contradicts how lean and continuous improvement programs work the best.

Successful managers integrate lean and continuous improvement initiatives into daily processes, with employees constantly asking how things can be done better. These process improvements are not add-on tasks, but ever-present aspects of company culture. Companies can successfully begin lean or continuous improvement with short training sessions, provided there is follow up to ensure employees implement their skills on a daily basis.

Specifically, when beginning or ramping up a lean or continuous improvement program, leaders should have their employees ask three questions: What should I be doing? How should I be doing it? Why should I be doing it? The answers should all feed into the same overall question: Does it support the customer?

Above all, the keys to successful lean and continuous improvement programs are engaging all employees and focusing on process. This combination leads to deeper employee engagement, added value for customers and waste reduction — creating a clear competitive advantage for companies that embrace a culture of continuous improvement.

…

Featured story in the Spring 2022 issue of Enterprise Minnesota magazine.