A few years ago, if you’d walked onto the C4 Welding shop floor on the right day, you may have seen Mikayla Asfeld working diligently.

But she wasn’t working for the company. At least not that day.

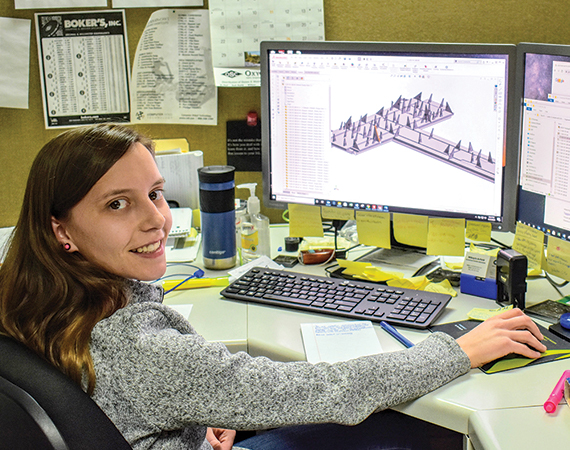

Asfeld, a full-time certified welder at C4, was doing college homework for her bachelor’s degree in engineering from Bemidji State University. C4 Welding — a Sauk Rapids-based full-service welding shop — was helping by giving her access to tools, equipment, people and resources.

Why?

Because they believed in her, and still do to this day.

With C4’s help, Asfeld went from a welder to one of the company’s go-to engineers. Her early displays of potential as a future company leader aligned perfectly with the company’s desire to encourage employee growth.

C4 President and COO Henry Ewers says helping Asfeld achieve her goals is part of the company’s approach to business.

“I think that’s really how you should grow companies,” Ewers says. “By growing your people.”

Asfeld’s rise from welder to engineer — and her use of the C4 Welding shop floor — was no fluke. Ewers says four of the company’s six engineers have gotten to where they are at C4 by first being welders. Investing in people is a model that has paid off for C4, a company Ewers says will do whatever it takes to retain good talent.

C4 Welding is the kind of welding company you go to when other places can’t do the job.

“We get into a lot of exotic materials, like Hastelloy, nickel, titanium,” Ewers says. “And there’s not a lot of people who are certified to weld them. We’re certified to weld over 150 different welding procedure specifications and procedure qualification records. And with that, when most customers call us, we’ve already got the certifications to meet their needs.”

But if you asked Ewers what he’s most proud of, it might be his company’s ethos of helping people such as Asfeld.

She came in as a certified welder and began learning the various types of unusual materials C4 Welding is known to work on. Ewers says she struggled at first. But once she got her footing, “She can run circles around some of our other welders who have been here for years. She probably won’t admit that, but I do.”

Asfeld had a goal, however, of becoming an engineer. And C4 Welding had a goal of helping people help themselves.

“She was working full time and going to school full time,” Ewers says. “There were times when we gave her some extra time off to work on her degree. But we knew it was going to be a great success for her and for C4 at the same time.”

At one point during pursuit of her bachelor’s degree, Asfeld needed to complete a project where she studied a company’s production process from beginning to end. Because she was already employed there, she chose to study C4.

“I was able to work with everyone on the floor, hands-on, figuring out exactly what they did for their job function,” Asfeld says. “And then being able to put that all into the process of how everything flows from the beginning, where it starts at customer support, all the way to the end when our product leaves the building, was a cool experience. By being able to talk to everyone about that sort of stuff, I learned stuff I probably never would have known otherwise.”

Asfeld appreciates the freedom C4 gave her to not only complete a project like this, but also to work full time and pursue a four-year degree. She says C4 was flexible with hours. (It also helped that she was able to complete the bulk of her bachelor’s degree online, even before the age of COVID.)

Ewers says he’s a firm believer in encouraging employers to strive for more; Asfeld and other engineers who were once welders are emblematic of that. Ewers says he hopes these employees have a firm grasp of the full range of the C4 Welding process. The support the company has given its employees, combined with the fact that they’ve grown professionally under C4’s guidance, is something Ewers predicts will go a long way in retaining talent.

“I don’t see them ever leaving C4,” he says. “They’re very happy right now. They work so cohesively as a team, and it’s just fantastic to see that.”

…

Featured story in the Spring 2021 issue of Enterprise Minnesota magazine.