Somewhere in the office of Ericco’s General Manager Mike Sorteberg is a tamarack post that used to hold up the ceiling of a turkey barn. The original buildings of the Ericco Manufacturing plant, located 17 miles west of Thief River Falls, Minnesota, have gone through a few remodels, Sorteberg says, but he keeps the old post “as a reminder of where we came from.”

This third-generation family-owned business remembers its beginnings as a matter of pride and as a guide to the future. Started in 1976 by farmer George Erickson, the company has evolved from a private machine shop to a 35,000-square-foot manufacturing company with more than 30 computer numerical control (CNC) machines that produce over a million high-quality parts per year for both high and low runs.

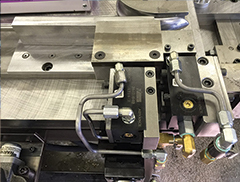

Ericco’s tooling department designs, develops, and fabricates custom tooling, and its quality department uses top-of the-line inspection equipment to ensure its products are of the highest quality.

Remembering where they came from

“This used to be a working farm,” Sorteberg says of the plant that has produced parts for Arctic Cat snowmobiles for several decades. Recently, Ericco expanded production to also include products for window frames and helicopter and drone parts.

Erickson bought the 320-acre property in the late 1940s on auction for about $4 per acre and farmed the land until the late 1960s when he switched to raising turkeys and livestock, according to his grandson Ben Erickson.

Ben, now president of Ericco, says his grandfather escaped a tough farm economy in the late 1950s by accepting a job as a tool and die maker with Bucyrus, a Milwaukee-based company that manufactured huge excavators.

“They knew farmers were mechanically inclined [with a] good work ethic, so Grandpa took the bait,” Erickson says. “He went to Milwaukee and learned everything he could about machining.”

George farmed another 10 years, then started a machine shop on the property. Ben’s father, Rick Erickson, worked with his father George in the shop while in high school. He studied drafting and machine tooling in college and worked a couple of years as a draftsman before he and his wife Sally moved back home to work for Ericco.

As the business grew, Sorteberg says, “We just filled the [outbuildings]. If you look on our website, at the two main production buildings, [you can see the] turkey barns. They’ve had a lot of work done to them, but that’s essentially what they were.”

From turkey farm to family business

In the beginning, Ben says, it was just a tool and die shop that did jobs for Arctic Cat, Polaris and Christian Brothers hockey sticks. “It wasn’t manufacturing high-quality production stuff.”

“Rick was kind of a one-man show,” says Sally Erickson, Ben’s mother. “He worked hard those early years and again when the company decided to take the leap with Arctic Cat and begin production machining.”

Sally was involved in the early years, mainly working with payroll and benefits. But she also held a full-time position as director of the Thief River Falls Developmental Achievement Center (DAC), which works with adults with disabilities. The insurance and benefits from her job covered Rick too, as Ericco didn’t yet have a benefits package of its own.

Cat parts

Located near Viking, Minnesota (population 103) and between Thief River Falls and Warren, Ericco’s primary business has always been with Arctic Cat.

“Not that many years ago, they were probably 99% of our business,” Sorteberg says. “Right now, it’s about 75% — still a big chunk. We’ve been in business [with them] for 44 years, and in some respects, we probably know them better than they know themselves. We’re kind of their right hand. We’ll do it right for them.”

When engineers and salespeople visit from Arctic Cat, he adds, “We know each other and we know what they’re working on, and how they might improve manufacturability of parts, reduce cost, thing s like that. That’s the kind of relationship we’ve had over the years.”

When Arctic Cat needed slide rails for all the different models of Arctic Cat snowmobiles, Ericco developed a process to curve each rail without having to work with the aluminum in a soft state and then heat treat it later for strength.

From 2008 to 2012, Sorteberg says, Ericco ran two production shifts to accommodate a boom in selling parts for Arctic Cat. But Ericco’s production decrease caused Arctic Cat’s inventory to stack up at the factory.

He and Rick had previously worked to expand their customer base, but when Arctic Cat was bought by Textron in 2017, they explored more customer options with greater urgency.

“If we aren’t moving ahead, we’re dying”

That same year, Ericco completed its ISO 9001 certification.

Sorteberg says it wasn’t in response to customer requests, but because “it made us a better company. Rick and I always said, ‘If we aren’t changing and moving ahead, we’re dying.’ So, we keep pushing to make ourselves a better company.”

Ericco was geared up and ready to accommodate Arctic Cat’s expected increase in production in late 2019, but then COVID-19 appeared and sent much of the state into lockdown. While some of Ericco’s parts were deemed “essential,” which allowed them to keep operating, unneeded employees were sent home.

When Arctic Cat started up again, their projections were conservative. No one knew what the economy would do. As a result, Ericco — which has about 30 employees — was forced to lay some of them off.

The connection between the two companies remains strong, and for years Ericco has sponsored various snowmobile racers.

“From the little kids on the Kitty Cats all the way up to the pros,” Sorteberg says, “we actively sponsor every year.”

And for the past two years, Ericco’s name has appeared on all Arctic Cat snowmobiles, race machines and clothing.

Despite a cut-back in production for Arctic Cat, Ericco managed about $6-$8 million in sales in 2020 and hopes new ventures will help them reach and exceed $15 million down the road. In addition to snowmobile parts, Ericco makes parts for a snow bike conversion kit built by MotoTrax of Spokane. Ericco also builds aluminum housings for airport runway lights as well as housings for lights on ships. Another unique client is SICO, for which Ericco makes frame pieces for portable dance floors.

Opportunities, possibilities

Recently Ericco landed a deal with Marvin Windows located in Warroad (85 miles northeast of Thief River Falls).

“They’re going to a whole new screen where they use extrusions rather than roll form framework,” Sorteberg says. “We’re in the process of building our production line, which is also going to be huge for the company.”

Other major opportunities have also materialized.

“We started visiting with Bell Helicopter and made some prototype parts. Now that’s taking off,” he says. “We can make prototypes and parts for helicopters, planes or drones, which we’re doing. As long as they don’t put a person on it, you don’t have to be AS9100 certified, but we want to pursue that.”

Enterprise Minnesota is helping Ericco pursue that aerospace certification, part of which will wrap up by early spring.

Sorteberg credits Enterprise Minnesota with keeping the company’s ISO efforts focused and on schedule. “When we started doing ISO, we thought we could do it ourselves [but] found out we needed help.”

Family business

Sorteberg has been with the company for 12 years. He and Rick had been close friends for more than 30 years when Rick was diagnosed with cancer in 2009. They had even played together in a gospel and blue grass band for several years.

After Rick’s diagnosis, Sorteberg says, “He didn’t know what his future was going to be. He knew he needed help, so he asked if I would come [to Ericco].

“[Rick’s] kids, who are actively in the business now, weren’t in the position to take the reins of the company [at that time], so he and I worked together. He had a fight with cancer for nine years. We worked together, and it was great.”

Although Sorteberg had no experience in machining in shops, he had worked for Arctic Cat for several years, and before that for 25 years for Homark, a home manufacturer in Red Lake Falls.

“Mike is talented in so many ways,” Sally says, “from working with the employees to all the other general management stuff, whether it’s insurance or safety.”

“That’s what I came for,” Sorteberg says. “To do the things that [Rick] knew he needed done, and I had experience in that. It’s funny how life gives you some curveballs along the way. But it’s all been good.”

Meanwhile, Ben and his sister Trudy had grown up with the business. Ben says he’s worked at the shop since he was old enough to push a broom. When he was young, his dad stacked pallets for him to stand on so he could reach the handle on a drill press and see how it operated. In the mid-1990s, when Ben was 15, he started working summers at Ericco.

After high school, he went to college with plans for law school but returned to the company. “It’s been a good choice. The best part of that decision was being able to work with my family.”

When Rick was diagnosed with cancer, Ben says, “He was wise enough to understand that I needed his many years of expertise, which I really did. So, throughout those years, he diminished his role a little bit more and more without ever completely disappearing.”

When she was just a kid, Trudy Erickson “kind of sensed” that she would work for the family business.

“The mechanical stuff always clicked,” Trudy says.

After graduating from high school, she studied engineering at the University of North Dakota. She briefly considered majoring in a medical field, but when the family learned of Rick’s cancer diagnosis, she says, it solidified in her mind that she would stick to her original plan.

She graduated with a degree in mechanical engineering and returned to Ericco. “We were growing really big at that time,” she says, “and I was needed.”

Rick was always there, Ben says. “He came to work every day until about a week before he passed away [in 2017]. He loved it here. He was a really great example for us.” The family, Ben says, “has worked together really well over the years.”

Extended “family”

Sally says she is proud that Rick and Sorteberg always treated employees, vendors and customers like friends and family.

Rick recruited Lisa Lowell to Ericco while she was eating a burger with a friend on a Saturday afternoon in Thief River Falls. “I knew nothing about Ericco,” she says. “Didn’t even know it existed.” Rick gave her a tour of the plant that afternoon, and two days later she was working as a machine operator. She thought her tenure would be a few weeks, but today, 16 years later, she is Ericco’s materials manager.

“I’d never seen a CNC machine before, didn’t even know what they were. There was a learning curve,” she says. “It can be hard work, but it’s also rewarding. You can walk out of here and say, ‘I built that, and I did a good job today.’”

Lowell says she is excited about Ericco’s work with Marvin Windows and Bell Helicopter, but more than anything, she is proud that what has kept her at Ericco for 16 years is the atmosphere.

“We’re a family here,” she says. “All of us truly care about each other.”

New employees

Manufacturers in Greater Minnesota all struggle to recruit from their own areas. But Sorteberg believes the talent is there. For the past several years (except 2020, with COVID-19’s restrictions), he has hosted a manufacturing day with Thief River Falls High School to let kids know about opportunities in manufacturing.

“It’s not the dirty grimy job that you thought,” Sorteberg says, “[but] high tech cool stuff. I team up with different companies [like] Marvin Windows. NDSCS (North Dakota State College of Science) in Wahpeton comes up and Northland Community College too. We talk about different aspects of manufacturing, job opportunities, and what’s out there.”

Today Sally, Ben, and Trudy are Ericco’s co-owners. George, now 90, still lives in the home on the property and stops by the shop regularly to keep up on Ericco’s progress. Sally still oversees payroll and benefits and represents the company on the Workforce Development Board for the Northwest Private Industry Council. She also serves on the Regional Alliance Committee. Ben, Ericco’s president, is busy coordinating with Bell Helicopter. Trudy, Ericco’s production engineer, focuses on automation logistics for the Marvin Windows project. Sorteberg’s talents have kept his friend Rick’s hopes alive for Ericco moving forward with exciting new possibilities.

And in the pipeline are three young Ericksons — Trudy’s daughter and Ben’s son and daughter — who will determine if Ericco will be a fourth-generation family-owned business.

…

Featured story in the Spring 2021 issue of Enterprise Minnesota magazine.