Owning and manufacturing sophisticated, intricate, precise assembly cells — some the size of a human hair — wasn’t AIT president Jason Smith’s original plan. And yet today, he knows starting, developing, and growing AIT to create precision components is the best plan, especially at home in central Minnesota where his family lives, and where he feels there is the best talent in the state.

Smith grew up in the St. Cloud area. Driven to understand how things work, he earned a degree in engineering from St. Cloud State University and jumped into a 25-year manufacturing career that would include research and development, engineering, and manufacturing experience.

A leadership change at the company he thought he might retire from prompted his course change. At the back of his mind was a long-held ambition of running his own business that he could shape with a vision of service excellence. And then he realized, that time had arrived.

So, he secured funding and bought his first machine. His last day as an employee was just two weeks before the official COVID shutdown. “After working for and with world-class companies including primes [big government contractors] like Lockheed Martin and BAE, I knew I wanted to start something amazing.”

Then just as he was dipping his toe in the manufacturing ownership pool, he faced the temptation to step onto a secure, predictable path with a company he admired. After touring their facilities and speaking with the team, they gave him a nice job offer, which perhaps a few months earlier might have carried his signature and start date.

“In a way that offer was a double-edged sword, or maybe it was a blessing, because when things got tough there was this feeling that if this doesn’t work out, I can find something,” Smith says. “But that’s not me. When I’m in, I’m all in, and that offer helped me realize this is what I want to do.”

With that Midwest mindset and the work ethic he admires in his employees, he set out to create a client-focused company where he would want to work and where employees would want to stay. AIT quickly achieved its ISO 9001 certification in three months with core competencies in machining, turning, EDM, automated assembly, high-speed metal stamping, and high-speed cable assembly. The company is focused on manufacturing intricate yet complex connectors and cables for the aerospace and defense industries.

Parts of the business development process were a shock to him. The Greater St. Cloud Development Corporation (GSDC) helped by providing essential connections, including to SCORE, a Minnesota group of volunteers who are expert business mentors. One consultant in particular, Jerry Hirschfeld, really stepped up for Smith and is now a life-long friend.

“I don’t think I could have made it without Jerry,” Smith says. “When I had a confidence gap, he filled it.” Hirschfeld’s years of running a business, including tech companies, provided Smith with ideas that drove inspiration and shared insights that helped him avoid problems. They still talk regularly, calls that Smith looks forward to.

With this support, Smith ran his single machine 24/7 and continued to grow the business. He was customer support, accountant, technology developer, and the guy who answered the monitoring systems on his machines at the facility at 2 a.m.

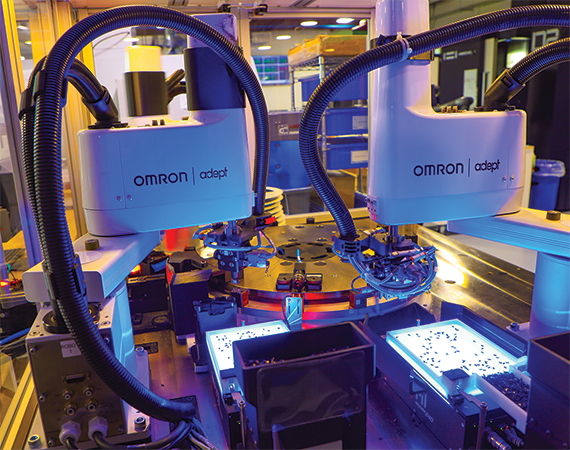

When you work with hair-fine pieces that serve as electronic contacts and physical connectors, precision is key. This is where his technology investments have really served to help support business growth. Robotic arms serve an integral role at AIT. These arms load raw materials, tend machines, assemble cells, and pick up these small components that are hard for the human eye to see.

The Nakamura MX-100, a more recent investment, also provides key capabilities by milling and turning complex geometries for parts. The team feels this amazing machine can make almost anything AIT needs in a single setup and operation, with precision milling and turning for intricate shapes and complex components. This addition to the AIT tech roster sets them on a road for additional growth and opportunities in new industries.

Over just a handful of years, AIT grew from a single, turn-key machine with one employee to a 25-person, three-shift team that has expanded into the energy and medical industries. “We have had a strong base and mature systems from Day 1,” Smith says. What sets AIT apart, he adds, is high-quality employees and a strong focus on customers. “We can compete worldwide.”

In 2024, Smith hired operations manager Scott Zadow to help the company evolve to the next level. Zadow recognizes how growth affects culture. “AIT is a young company, and we know as the SKU numbers increase, so does the amount of employee stress,” he says. Among his priorities are getting what he considers the company’s tribal knowledge out of the heads of a few, and “ensuring we have documentation, control plans, and processes to maintain our high standards and reinforce strong work/life balance.” One near-term goal is moving the team to a four-day work week.

Next generation knowledge sharing

Smith also understands that AIT’s future success hinges on the company’s ability to attract and retain young talent. The company offers marketing and engineering internships, and this year hired recent University of Minnesota mechanical engineering graduate Sam Peterson.

“I am really impressed with him,” Smith says. “He is killing it.”

Peterson was looking for an opportunity to do more than mechanical engineering at his first job. “I knew many design engineers never see their designs implemented because the manufacturing is outsourced,” Peterson says. AIT offered design work, automation, robotics, and assembly. “I have been able to work on some pretty big projects. I worked on the design of complex interconnect components that leverage the advanced capabilities of the Nakamura MX-100, and I helped justify that purchase.” And now that the Nakamura is in place, he designs components that enter the MX-100 to be cut.

Peterson says he was hands on at every stage of the design process from early rendering and modeling to taking it to the floor and working with the experienced machinists and operators directly.

Growth through technology

Investing in key technology, like the Nakamura, is capital intensive and yet critical investment for manufacturing growth. “I started AIT with one machine, and if I left it at that life would be simple but pretty boring,” Smith says. “Growth comes through key technology investments.” In 2024 alone AIT invested $2.5 million in equipment including the Nakamura and the Citizen machine, which is a 12-axis, or small diameter, machining center.

Smith acknowledges several local partners for their help, including the GSDC (Greater St. Cloud Development Corporation) and DEED (Minnesota Department of Employment and Economic Development), the St. Cloud Community, and the State of Minnesota Investment Fund (MIF), which helped support their equipment investments.

And now, nearing the 5th anniversary of AIT next year, Smith takes little time to look back except to reflect on two things. First, would he do it again? “In the roughest times, you just have to put your head down and go,” he says with a chuckle. “And yes, on most days, I’d do it again.”

Second, did he build the customer-focused company that holds a unique position for how they respond to client needs, especially if something isn’t perfect? “We are definitely that company and that team. I knew we could find the talent and the right people here at home in central Minnesota — and truly our people are why AIT is successful and will continue to grow.”

Return to the Fall 2024 issue of Enterprise Minnesota® magazine.